|

|

|

Doidge Fastenings Ltd.

Rivets, rivet setting machines and fasteners

|

|

|

|

| 1 - 2 George Baylis Road, Berry Hill Industrial Estate

Droitwich, Worcestershire WR9 9RB

TEL: 01905 779448 FAX: 01905 796643 info@doidge.com |

|

|

|

|

|

|

|

|

|

|

| Standard Spring Centre Anvil |

|

The anvil consists of five basic parts body, centre pin, spring, centre pin, adjusting screw and lock nut.

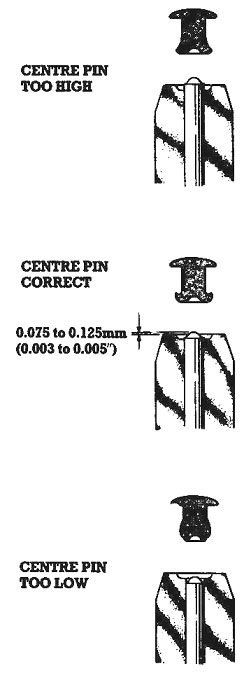

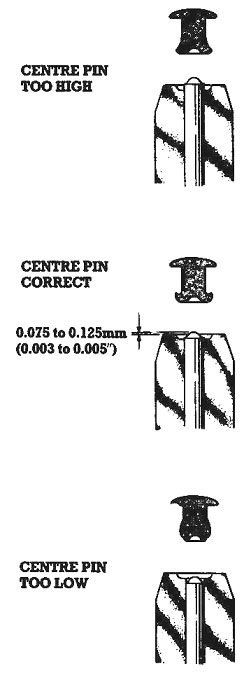

The adjustment of the centre pin height relative to the surface of the anvil body is common to all anvils setting semi-tubular rivets. The correct setting of the centre pin is with the tip of the pin 0.075 to 0.125mm (0.003" to 0.005") above the profile of the body of the anvil as shown. If the centre pin is incorrectly adjusted, a poor fastening will result, as illustrated.

|

|

| Replacing the Centre Pin |

|

Lightly grip the two flats on the anvil body in a vice. Loosen the lock nut and remove the centre pin adjusting screw. The spring and centre pin can be removed from the anvil body. Insert the new centre pin and replace the spring, centre pin adjusting screw and locknut. NOTE New centre pins are manufactured to top limit, to allow for wear. The pin should slide freely in the anvil body. If it does not do so, carefully reduce its diameter by polishing.

|

|

| Height Adjustment |

|

| Turn the centre pin adjusting screw until the formed end of the pin makes a continuous surface with the curvature in the anvil body when the pin is fully depressed. Tighten the locknut without moving the adjusting screw. There is a tendency for new pins to sink when first used. Check and adjust if necessary. |

|

| © 2002/2003 Doidge fastenings Ltd. |

|

|

|

|

|

|

|

|

|

|

|

|